The layout design of PCB (printed circuit board) directly affects the performance, stability, and manufacturing cost of the product. Following reasonable layout principles can enhance signal integrity, reduce electromagnetic interference (EMI), and improve production efficiency. The following are the key specifications for PCB design:

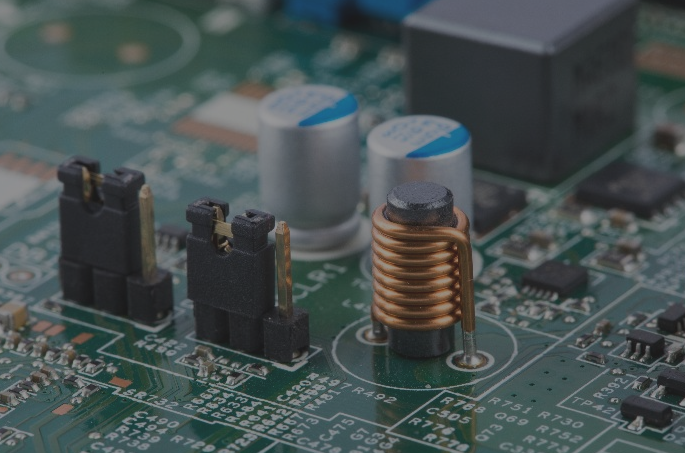

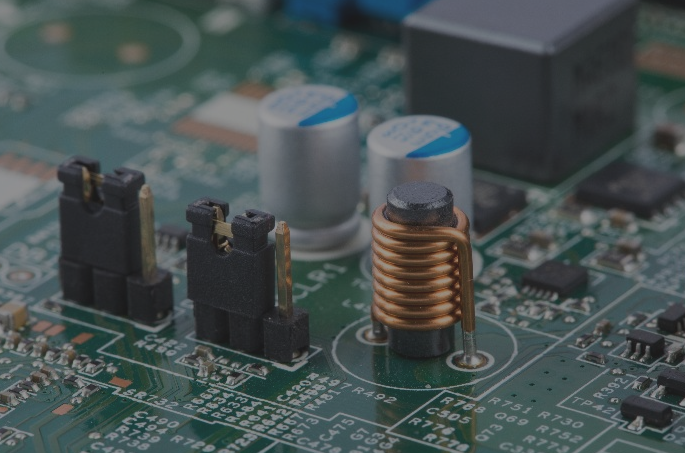

1. Principles of component layout

functional zoning

Arrange components according to functional areas (such as power supply, circuit control, signal processing) to reduce interference and improve maintainability.

thermal management

High power components should be kept away from temperature sensitive devices and equipped with heat dissipation copper foils or vias to ensure uniform temperature distribution.

Mechanical constraints

Pay attention to the distance between components and board edges or mounting holes to avoid processing and assembly issues.

2. Wiring rules

Signal Integrity

The high-speed signal should be as short and straight as possible, avoiding 90 ° bends to reduce reflection and crosstalk.

Power supply and ground wire

Using a complete ground plane to ensure a low impedance return path; Widen the power cord to reduce voltage drop.

differential signal

Maintain equal and equidistant lengths to ensure impedance matching and reduce interference.

3. Electromagnetic compatibility (EMC) design

Minimize loop area

Shorten the signal circuit to avoid EMI caused by high current loops.

shielding design

Add grounding shielding or metal casing to critical circuits to enhance anti-interference capability.

Filtering and decoupling

Add filtering capacitors at the power inlet and configure matching resistors at the critical signal end to suppress high-frequency noise.

4. Manufacturability and testability

Reasonable line spacing

Follow the process standards to ensure that the line width, spacing, and pad size match the process capability, avoiding short circuits or open circuits.

test point

Reserve test points at critical locations for circuit diagnosis and to improve mass production yield.

Through-hole optimization

Reduce unnecessary vias to avoid increasing manufacturing costs and signal loss.

Niuwei Industry - Professional PCBA Solution Provider

Niuwei Industrial has been deeply involved in the PCBA industry for many years, providing high-quality PCBA design, manufacturing, and customization services. The company has advanced PCBA production lines and strict quality management systems, and has obtained certifications such as ISO9001 and BSCI to ensure that its products comply with international standards such as 3C, CE, FCC, RoHS, etc. Niuwei Industrial provides one-stop OEM/ODM services, focusing on high-precision and high reliability PCB manufacturing. Its products are widely used in communication equipment, medical electronics, industrial control, automotive electronics and other fields. Choosing Neway Industries means choosing professionalism and quality assurance.