Project Background

A certain intelligent security enterprise plans to launch a new type of camera that supports 4K high-definition video, AI facial recognition, and night vision enhancement functions. Its core requirements are:

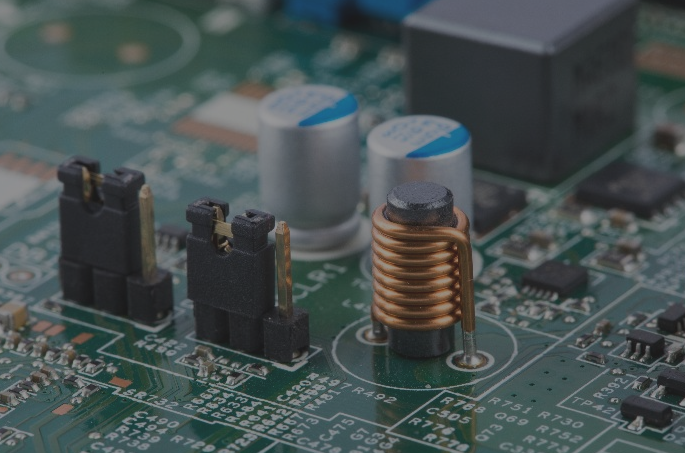

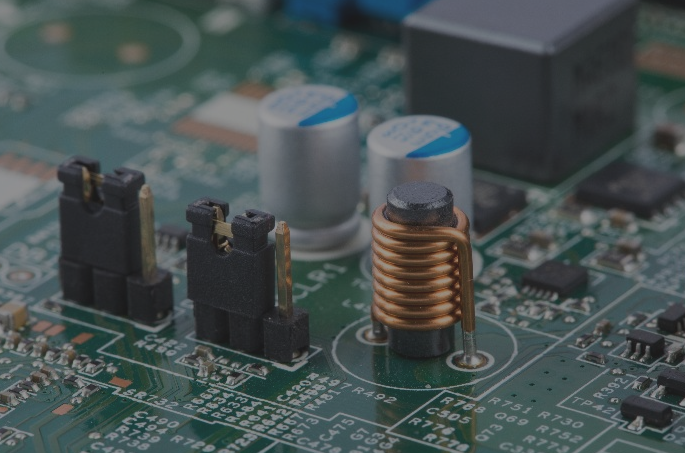

High integration design: requires the integration of high-performance processors, multiple sensors, and wireless communication modules within a limited space.

Signal integrity requirements: 4K video transmission requires strict impedance control to ensure signal interference free.

Rapid mass production requirement: 5000 sets of motherboards need to be produced within 6 weeks and support flexible expansion of subsequent orders.

Niu Wei Industrial's OEM solution

Design optimization and DFM review

Signal integrity optimization: In response to the demand for 4K video transmission, the engineering team of Niuwei Industrial optimized the PCB layered design through simulation software, using differential routing and impedance matching technology to reduce signal attenuation to 60% of the industry standard.

Manufacturability Review: Through DFM (Design for Manufacturability) analysis, adjust the component layout to reduce the movement distance of SMT mounting heads and improve production efficiency by 15%.

Production Execution and Quality Control

High precision SMT mounting: Using Siemens HS60 high-speed surface mount machine, the 0201 component mounting accuracy is ± 0.03mm, and the welding yield rate reaches 99.95%.

Lead free soldering process: using environmentally friendly lead-free solder, combined with 3D SPI (solder paste inspection) and AOI (automatic optical inspection) equipment, to achieve full process quality monitoring, with a defect rate of less than 0.02%.

Functional testing loop: Conduct 100% functional testing on each motherboard, including video transmission stability, AI algorithm compatibility, and night vision enhancement effect, to ensure zero defect delivery of the product.

Supply chain collaboration and delivery

Agile Supply Chain Management: Leveraging the Yangtze River Delta electronic component cluster, Niuwei Industrial schedules supplier inventory in real-time through an ERP system to ensure critical chips (such as processors and sensors) arrive within 48 hours, avoiding production interruptions.

Flexible production capacity configuration: Through flexible production line design, seamless switching from trial production of 5000 sets to mass production of 500000 sets is supported to meet customer market expansion needs.

Project achievements

Technological breakthrough: Successfully solved the problem of 4K video signal interference and micro spacing welding, and the product performance exceeded customer expectations.

Cost optimization: By scaling up procurement and simplifying testing processes, we help customers reduce single board costs by 12% and enhance market competitiveness.

Long term cooperation: With this performance, Niuwei Industrial has become a core supplier for customers and will continue to undertake OEM orders for its full range of intelligent security products.

Case highlights

Technical empowerment: By optimizing signal integrity and conducting DFM reviews, we can proactively mitigate production risks and shorten research and development cycles.

Quality closed-loop: From solder paste inspection to functional testing, advanced equipment such as AOI and X-Ray are used to ensure zero defect delivery of products.

Supply chain resilience: Building a "2-hour economic circle" based on geographical advantages to achieve rapid replenishment and flexible production of components.